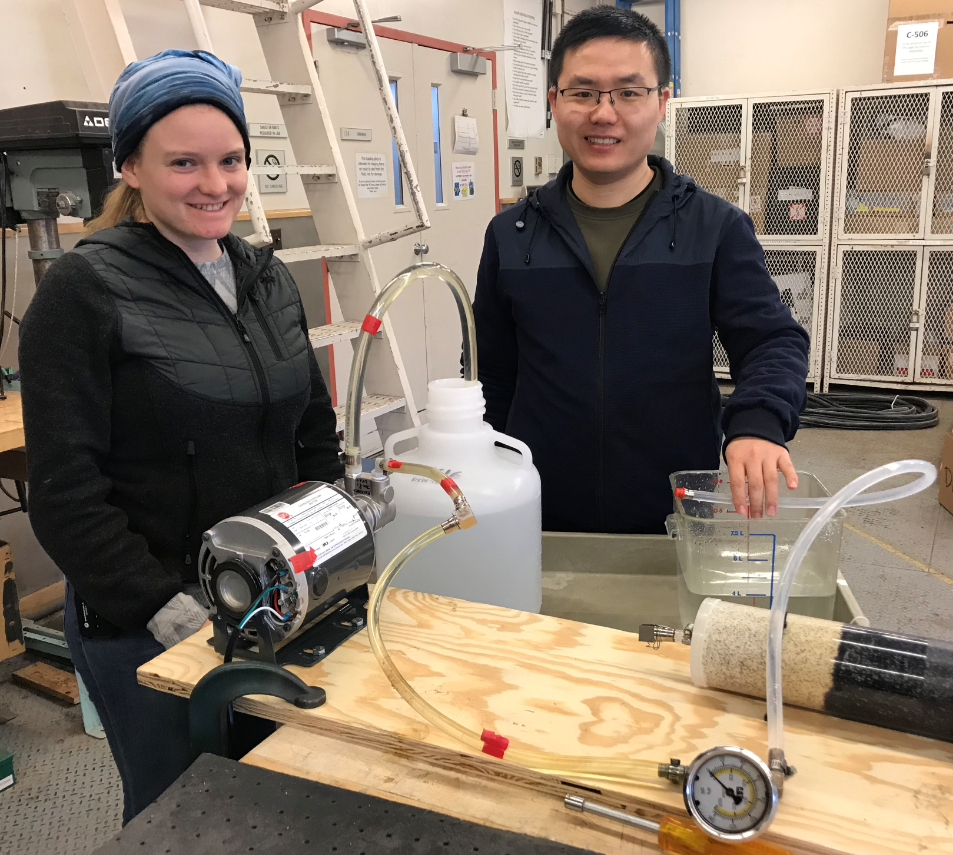

Yesterday, we received replacement pumps for our Sodium Doppler Lidar’s YAG laser power supply chiller. First, we set up a testbed in the Crary lab field staging party area to set the pump we received to 60 psi. We then installed the new pump along with a motor, two water filters, and one transformer back to the crowded laser power console. Fluid systems aren’t something you expect to deal with when you study Lidar, we have enjoyed putting our engineering degrees to use. Actually, Jackson’s experience working on neighborhood pools has been the most relevant- the laser’s cooling system is similar to what you would see in a soda carbonation system (uses the same pumps and motors!), and is kind of like a miniaturized, simplified pool. My experience with satellite propulsion occasionally comes in handy as well.

Amanda and Xianxin testing pump pressure

Jackson during pump/motor installation

Without the coolant system, we can’t stabilize the temperature of the flashlamps, and can’t turn the system on. Today, we got the laser running for the first time in 10 days! We were able to finish alignment and tuning, and from this we were able to double the power at the laser output compared with when we arrived at the ice. A great day’s work! Tonight, we are hoping for clear skies so that we can start collecting data again.