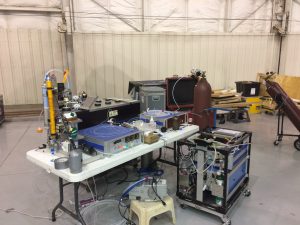

With so many instruments and some overlapping measurements in the airplane, it’s important that we know exactly what and how much we’re measuring to make sure we provide the most accurate results and that all the instruments agree with each other. In order to accomplish this,we have come to Salt Lake City well equipped with calibration sources for a wide range of compounds, many of which can be measured on multiple instruments.

Calibration source storage area

Both the nitrogen oxide cavity ring-down instrument (NOxCaRD) and the I– CIMS measure a variety of nitrogen oxide compounds, so we do a lot of cross-comparisons between these instruments. We cross-calibrate with known concentrations of HNO3, HONO and N2O5.

Carrie strings a line of tubing to run a calibration source to the inlet on top of the plane

For the technically and chemically inclined here are some details on the actual sources (those not interested can skip to the next paragraph): We get HNO3 from a simple permeation tube setup, which contains solid HNO3 permeating out of the tube at a known rate. Producing N2O5 is slightly more involved. We actually have two different calibration sources that both use the same reaction of NO2 + O3 to generate N2O5, but in different ratios. O3 is produced from air passed over a UV lamp. The NO2 is ordered from a gas supply company. The N2O5 produced is constant if the reaction conditions are held constant, but the final concentration can be controlled by dilution with air. HONO is produced from the reaction of HCl (from a permeation tube) and NaNO2. For the primary NOxCaRD calibration, NO2 is produced through reaction of known amount of O3 with NO.

The inlets on top of the plane, with HONO added to the middle inlet

Once we have all these sources set up, we have to add them to the instruments. In the lab, this is usually straightforward, but right now our instruments are packed into a tiny airplane and set up to pull in air from outside the plane while flying. This means some of the instruments have their sampling inlets on the sides of the airplane, while others have inlets sticking up through the airplane roof.. So, we all spend a lot of time climbing all over the airplane and handing sources up and down so we can sample the different compounds we want to test. We needed to devise a creative method for adding the calibration sources to NOxCaRD because one of its inlets is on the roof and heated to 650°C (over 1200 °F!). We ended up wrapping the inlet with a layer of insulation and using a hose clam

Carrie hands Dorothy a calibration source to feed into the inlet

p to hold a piece of rod, acting like a ringstand, which you may remember from your high school chemistry lab. We attach a simple clamp to the rod that holds the tip of the ⅛” quartz in our hot inlet. The I- CIMS inlet is on the side of the plane and is unheated, so adding sources is much simpler. When we calibrate both NOxCaRD and I– CIMS with the same source (cross-calibrate), we are careful to leave all the tubing the same to make sure we’re adding exactly the same amount to both instruments, but we simply put the quartz directly into the CIMS inlet on the side of the plane.

We usually run calibrations on days when we’re not flying. It snowed for several days last week, so we were unable to fly, but we were able to run a lot of calibrations, so the instruments are all set for the inversion that is currently starting in the Salt Lake City area.